Mission Statement:

Our mission is to showcase the means for all countries to achieve self-reliance, and independence, with the use of advanced technologies, and materials, available today.

Project Overview:

This project is geared to help build a natural rubber industry, in Southern Oregon, in order to show the availability of high density growing systems that reduce water used, while growing the rare Kazakh 'Rubber Root' dandelion (Taraxacum koksagyhz), noted for its content of high quality natural rubber latex in its thick, long roots, and the desert rubber plant, Guayule (Parthenium argentatum), used by the Aztecs long ago for their sacrificial ball games.

The Kazakh Dandelion, known as 'Rubber Root

Thailand is the biggest exporter of natural rubber in the world, with smallholders, families with two to four acres of land, growing clonal rubber trees from the original Brazilian trees imported to Asia. Child labor is an issue, low wages with families making 2USD to 4USD per day from their labor, being exposed to toxic ammonia and acids used to coagulate the rubber latex they tap from their trees into little bowls that catch the dripping latex. https://gpsnr.org Global Platform For Sustainable Natural Rubber in Kuala Lumpur, Stefano Save, Director, GPSNR ... www.ted.com/talks/stefano_savi_sustainability_together_forward ...

Our nation now uses 1.5 million tons / 3 billion pounds of natural rubber, per year, with the global demand of 15 million tons of this vital commodity, used by American producers of 40,000 products that depend on it, including tires. In 2020 a million rubber trees (Hevea brasilensis) died due to fungal leaf blight in Asia, with a 5.7% reduction in the overall global supply. In order to upscale production of natural rubber, using a water based extraction system, it will require us to use high density vertical growing systems, in our greenhouses, and plant tissue micropropagation of clonal plants to greatly increase our plantings. Dr. Cornish projects a global demand of over 30 million tons of raw natural rubber per year by 2026.

Commodity Price Chart for Natural Rubber -- Cents Per Kilogram on Right Side of Chart

Over the years ahead we will scale up our production of plants for natural rubber, specialty food /gourmet markets, biochar products, to meet the needs of America, to end our dependence on food and raw natural rubber imports, and to end our dependence on Asian imports. With our scalable plan we will turn America from being an importer to become the first country to export raw natural rubber, with 95% purity, to the

growing global markets, using a water-based extraction process developed by the Program of Excellence in Natural Rubber (PENRA) at Ohio State University. https://u.osu.edu/penra

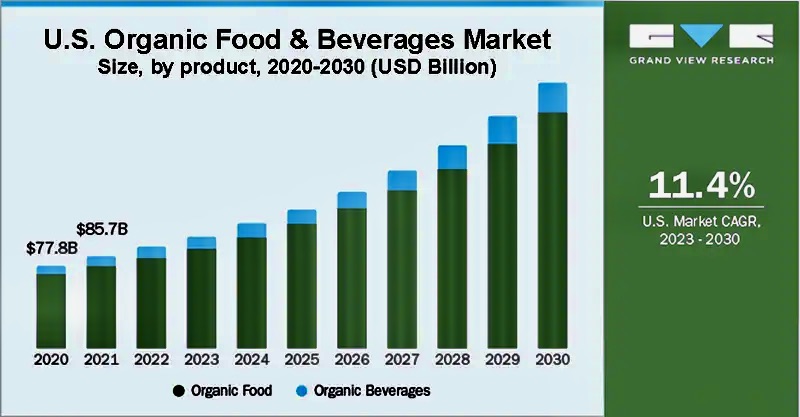

Organic Food Market Projection to 2030

With hundreds of gourmet food plant species to be grown on our food forest farm sites, we will have something for every palate, and cuisine, being able to sell to emerging global specialty food markets.

<www.marxfoods.com> is a fifth generation specialty food brokerage in Seattle, they market produce

their network of growers around the world.

Greenhouse Cultivation of the Desert Rubber Plant, Guayule

With Digital Magnetic Inverter (DMIG) power units on our farm sites we will use the new atmospheric water generators now available from a number of companies. Air to Water systems are now available from https://quenchinnovations.com .... https://rainmakerww.com .... https://air2watersolutions.com, as long as you have a power source to run them, which we will have on our farm sites from https://3-bears.com ...

Over Six Hundred Species of Plants Valued for Fiber, Food, Medicinals and Hardwoods

With off grid power and water generators, and the land now available in Oregon, with over 200,000 deeded acres, for our use of permaculture / food forest plantings outdoors for temperate species, and inside greenhouse structures for tropical species, we will showcase how to live gently with the living land, while regenerating depleted soils. Our continual scaling up of production capacity to grow plants that yield a high quality natural rubber for America's current and future needs will keep us busy.

Food Forests of the Future for Deep Biodiversity

By working with Richard Hurding, Executive Director, at Zelfo Technology GmbH, in Germany, www.zelfotechnology.com we will be able to turn our surplus plant cellulose into Bio-thermoplastic, to

be used as feedstock in mega-scale 3d printers from the Italian company, WASP 3D, www.3dwasp.com.

They offer their 'infinite digital manufacturing process' and line of 3d printers, including one that is able to handle cellulose material, and concrete, to literally print out homes, and entire communities. Their WASP 12M Big Delta 3d printer can print out objects and structures to 12 meters / 36' high. A new geopolymer

concrete from www.ultrahighmaterials.com is 8x stronger than conventional concrete, it can be used

as a feedstock to the mobile extruder / printhead of the WASP 3d printer to print out homes. We will

also be using the tracked, mobile 3d concrete printers from www.cybe.eu to make items of value, and

tiny homes, as well as planters for indoor food production in homes. Cybe uses a mortar in their printers that is 14x stronger than concrete.

Our project will create a showcase for leading edge technologies that we will deploy globally. With the Southern Oregon University, in Ashland, we will be able to offer internships to the students who want to help us build a sustainable 'Green' future for all nations, and people, to enjoy. www.sou.edu In nearby

Klamath Falls the Oregon Institute of Technology www.oit.edu offers us a great pool of talent from their engineering school, and new Alternative Energy Engineering degree program.

You can contact Greg A. O'Neill, Founder/CEO, White Tiger Farm, at his e-mail address below to dialog over this awesome opportunity to demonstrate that clean energy, fiber, food and water can be produced anywhere. Visionaries, artists, designers, engineers, and other creative folk, with the passion to pioneer the future are welcome to join us as Earth stewards for a 'New Earth' paradigm through regenerative agriculture.

Email ---- goneill51@gmail.com ---- http://about.me/goneill ----

https://www.linkedin.com/in/goneill

Website design by Greg O'Neill

Click Here - This Link will take you to Page 2 of White Tiger Farm LLC.

The Link above will lead you to more pictures, and related information on this venture into the sustainable future.